The term “antibody production” refers to the process of creating usable antigen-specific antibodies. It involves the preparation of samples of the target antigen and safely injecting it into a laboratory animal or synthesis of the genetic material related to the antibody that recognizes the antigen of interest.

A large quantity of antibodies is produced in the animal’s serum. While polyclonal antibodies are extracted directly from the animal’s serum, monoclonal antibodies are typically derived from the spleen of the host animal.

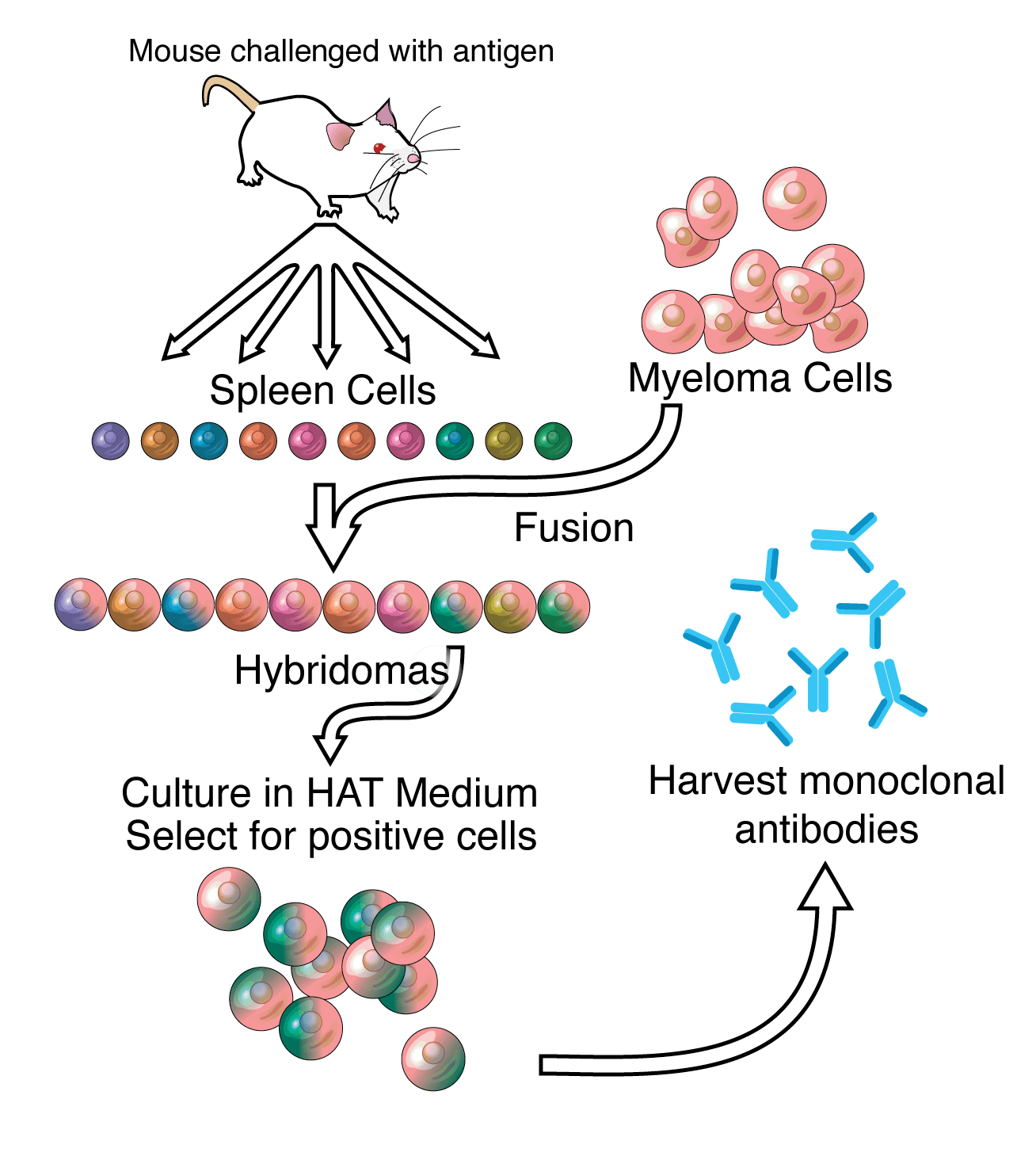

The development of monoclonal antibodies involves fusing the antibody-secreting spleen cells from the immunized animal (usually a mouse) with immortal myeloma cells. The process creates a monoclonal hybridoma cell line which then extracts the specific antibody in the cell culture supernatant.

Antibody Production Steps

The steps involved in antibody production and development depend on the type of antibody that is needed. Therefore, the steps that are outlined will follow monoclonal or polyclonal antibody production.

Steps to Produce Monoclonal Antibodies

Monoclonal antibodies are usually produced in animals like mice, rabbits, chickens, and rats, but overwhelmingly the most commonly used model is the mouse, however, rabbit is a close second due to its immune system’s ability to have a robust response to antigen presentation. Monoclonal antibody production steps involve the following:

- Animal Immunization

The first monoclonal antibody production step is to immunize the animal with purified antigen conjugated to a substrate like KLH. The investigator injects the antigen complex subcutaneously along with an adjuvant and repeats the injection at multiple sites several times along a predefined timeline that is dependent on antibody titers taken throughout the procedure. The multiple injections will increase the stimulation of the B-lymphocytes that respond to the antigens.

The animal gets a final dose of the antigen three days before it is killed, only that this time, the investigator administers it intravenously. When the antibody reaches a sufficient titer, the investigator euthanizes the mice and removes the spleen to be used as a cell source for fusion with myeloma cells.

- Fusion and Selection

Hybridomas result from fusing antibody-producing spleen cells with cells derived from myeloma cells. The resulting hybridoma cell line is capable of unlimited growth. Myeloma cells must have rapid growth, high viability and are grown a week before cell fusion.

- Antibody Purification

You will likely need to purify monoclonal antibodies before using them. The gold standard for monoclonal antibody purification is Protein A or Protein G affinity chromatography. It is a technology that has been incorporated by top scientists because of its capabilities and performance. However, for clients who need a higher level of purity, other advanced purification methods can be used, including size exclusion chromatography or antigen-specific affinity chromatography.

- Quality Control

Quality control assays are used for testing the quality of monoclonal antibodies after the purification process is completed. The ELISA test is the most preferred method for establishing monoclonal antibody quality.

Polyclonal Antibody Production

- Antigen Preparation

The polyclonal antibody production process starts with preparing the antigen, which is usually an amino acid sequence derived from the antigen. You must ensure that select antigens that are unique and immunogenic, especially when binding with conformational epitopes is desired. Any impurity in the antigen can result in antibodies that are more active against the impurities than the target antigens.

- Animal Immunization

At Green Mountain Antibodies, we use special adjuvants to increase the immune response for polyclonal antibody production. Freund’s adjuvant is one of the commonly used in research. You can inject the antigen intramuscularly, subcutaneously, or intradermally into the chosen animal (usually a rabbit).

Booster immunizations are administered 4 – 8 weeks after the priming immunization. It then continues at 2- to 3-week intervals. The animal is bled after each booster immunization and serum is prepared from whole blood.

- Antibody Purification

A good purification method for polyclonal antibodies is affinity purification. The purification method can enrich Immunoglobulin G in the unpurified serum and remove the unwanted proteins. To specifically target a polyclonal antibody from antiserum, we use antigen-specific affinity purification.

- Quality Control

After purification, quality control tests are carried out to check the quality of the polyclonal antibodies produced. Its concentration is evaluated by absorption at A280 (280nm), and its purity is checked using SDS-PAGE.

Interested in doing business with us? Why do not you contact us today! Contact Green Mountain Antibodies for a full range of services for creating new monoclonal antibodies or producing antibodies: 802-865-6230